Sustainable Catalysis

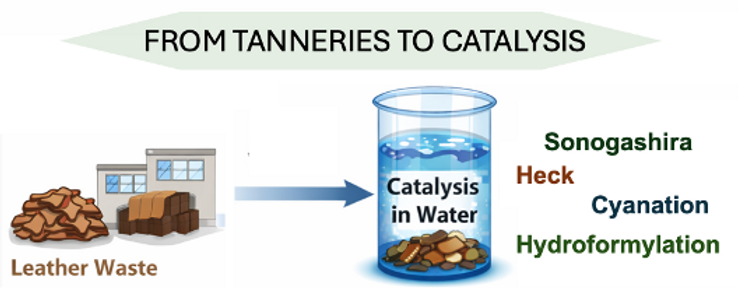

While liquid waste management has been widely investigated and effectively implemented, solid waste materials generated from agricultural and industrial activities still face limited applications due to their classification as special waste. This limitation represents a major opportunity for valorisation within green and circular chemistry frameworks. Our research integrates two complementary projects aimed at transforming industrial and agricultural solid waste into functional materials for sustainable catalysis. The first project focuses on the upcycling of vegetable-tanned leather wastes into multifunctional auxiliary materials for transition metal–catalysed reactions performed in water under mild to moderate conditions. These materials enable key industrial transformations, including hydroformylation, Suzuki coupling, copper-free Sonogashira, Heck, and cyanation reactions. In addition to promoting catalytic efficiency, they improve reaction handling, simplify downstream processing, and allow the replacement of conventional organic solvents with water. Environmental performance was evaluated through Green Chemistry metrics and Life Cycle Assessment, demonstrating clear sustainability advantages compared to traditional methodologies. This approach promotes material loop closure between the tanning and chemical industries and advances industrial symbiosis. The second project addresses agricultural solid waste by introducing micronized waste wool as a biogenic solid emulsifier for metal-catalysed organic transformations conducted in the absence of organic solvents. The wool generates stimuli-responsive Pickering-type emulsions in aqueous systems applied to Suzuki and Sonogashira cross-couplings and hydroformylation. Under dielectric microwave heating in the presence of a metal catalyst, the wool–water system forms Pickering-like micellar structures that compartmentalize palladium or rhodium species at the protein–water interface. This interfacial organization enables highly efficient transformations with excellent yields and regioselectivities. Scalability studies confirmed the robustness of the methodology and demonstrated the recyclability of both the wool emulsifier and the aqueous catalytic phase after simple centrifugation. Protein characterization revealed that catalytic performance correlates with the sulphur-rich protein content and amino acid distribution of the biomass. Together, these projects demonstrate how solid waste streams from the leather and agricultural sectors can be transformed into high-value functional materials for catalytic processes. By eliminating synthetic surfactants, organic co-solvents, and separation solvents in transition metal–catalysed reactions, this research advances circular chemistry and establishes new strategies for converting waste into sustainable synthetic tools.